Descrición

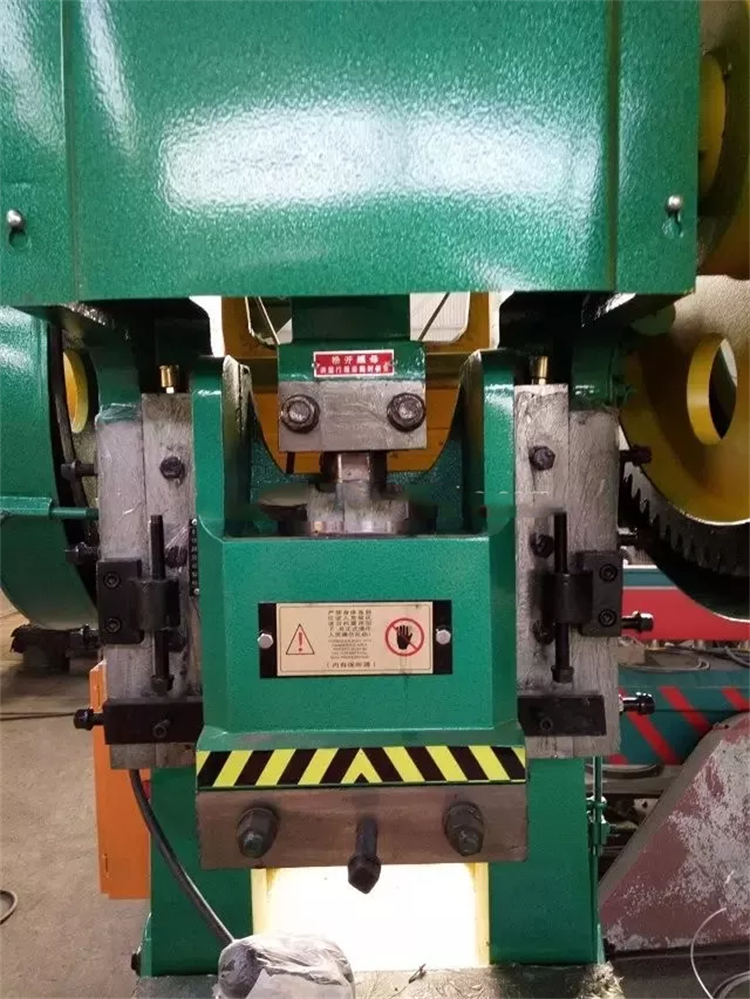

JB23 punch press is a suitable open type crank press featuring a left and right open type machine body (i.e. C-shaped machine body). Its steel plate welded body has high shock-absorbing performance. Its novel overall design gives the machine elegant appearance. Its throat has certain depth. The compact structure makes the use convenient and operation safe. The punch press is equipped with a turn-key rigid clutch, a cam band brake and a press-down type safety device. Its working table is open on three sides, so the mold loading and unloading and operation are convenient. The punch press is widely used for it provides good conditions for mechanization and automation. And as main equipment for plate punching production, the punch press can be used for punching holes, blanking, trimming, bending, shallow stretching and forming in national defense, aerospace, automobile, tractor, motor, electrical appliance, bearing, instruments, agricultural machine and tool, bicycle, sewing, mechanical appliance, daily hardware and coinage departments.

The machine of whole structure and characteristics :

1.C-Type Steel-welded frame, high rigidity and less deformation Compact,wide body frame eliminating vibration for improved idelife and machine.

2. Rigid construction guarantees exact die mating,Six-side long rectangle guides of the slide with high moving precision and high accuracy, extending the service life of the die.

3. Highly advanced, rigidly supported gears, operate in oil bath without any noise saves space, reduces, shaft deflection, increases gear life.

4.High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

características

5. J23 series are general open-tilting power press with simple structure ,reliable performance and easy operation .J23 can adopt rigid turn-key clutch .

6.So, it is convenient for operation and maintenance .J23 can also adopt emergency stop service to make the slider block suddenly stop on the range of 0-135 degree,and the photoelectrical protector device is optional .

7.J23-100B and J23-125 are special among the J23 series .Their main body is cast in iron .The cranked axle is settled

vertically.Eccentric sleeve makes easy adjustment .And there is also pneumatic friction.Therefore ,J23-100B and J23-125 enable to work with small impact and sationarity and make slider block stop at any position .

Product Detail

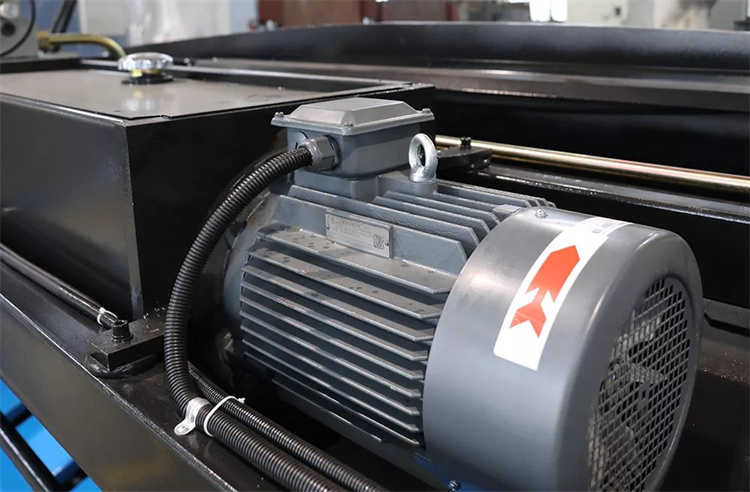

Main Motor Workbench Rigidly supported gears

Using Siemens motor guarantees the Six-side long rectangle guides Highly advanced, rigidly supported

machine service lifeand reduce the noise of the slide with high moving gears,operate in oil bath without

when working Bosch Rexroth Oil Pump precision and high accuracy, any noise saves space,reduces,

12345647895566632233 extending the service life of the die. shaft deflection,increases gear life.

Product Display

Parámetro

规格型号 Model | JB23-100T | JB23-80T | JB23-63T | JB23-40T | JB23-25T | JB23-16T | JB23-10T | |

公称力 Nominal Force(KN) | 1000 | 800 | 630 | 400 | 250 | 160 | 100 | |

滑块行程 Carreira de deslizamento (mm) | 130 | 115 | 110 | 100 | 70 | 60 | 50 | |

滑块次数 SPM (min-1) | 45 | 45 | 50 | 70 | 80 | 120 | 150 | |

封闭高度 Die Height Adjustment ( mm) | 400 | 385 | 380 | 350 | 280 | 245 | 160 | |

最大封闭高度调节量 Max. Die Height (mm) | 60 | 60 | 60 | 60 | 50 | 40 | 30 | |

滑块中心至机身距离 Between Slide Center & Frame(mm) | 280 | 260 | 250 | 220 | 185 | 160 | 120 | |

工作台尺寸 Table size( mm) | 前后 front and back | 530 | 490 | 450 | 400 | 320 | 280 | 230 |

左右 left and right | 830 | 760 | 700 | 650 | 540 | 455 | 370 | |

工作台孔尺寸 Table hole size(mm) | 190 | 170 | 170 | 140 | 130 | 130 | 100 | |

立柱间距离 Distance between columns(mm) | 365 | 310 | 310 | 245 | 200 | 215 | 180 | |

横柄孔尺寸 Shank Hole | 直径 Dia(mm) | 60 | 60 | 60 | 40 | 38 | 35 | 30 |

深度 Dpth(mm) | 80 | 80 | 80 | 80 | 60 | 60 | 50 | |

工作台板厚度 Bolster Thickness (mm) | 95 | 90 | 85 | 70 | 50 | 45 | 40 | |

机身最大可倾度 Max. Inclined Angle (°) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

电动机 Motor Power( kw) | 7.5 | 7.5 | 5.5 | 3 | 2.2 | 2.2 | 1.5 | |

外形尺寸 Outline Size | 前后 mm | 2000 | 1700 | 1700 | 1500 | 1200 | 1100 | 850 |

左右 mm | 1300 | 1250 | 1200 | 1100 | 800 | 750 | 570 | |

高mm | 2800 | 2600 | 2450 | 2300 | 2000 | 1600 | 1530 | |

总质量 Weight(Kg) | 5500 | 4500 | 3500 | 2500 | 1100 | 700 | 350 | |